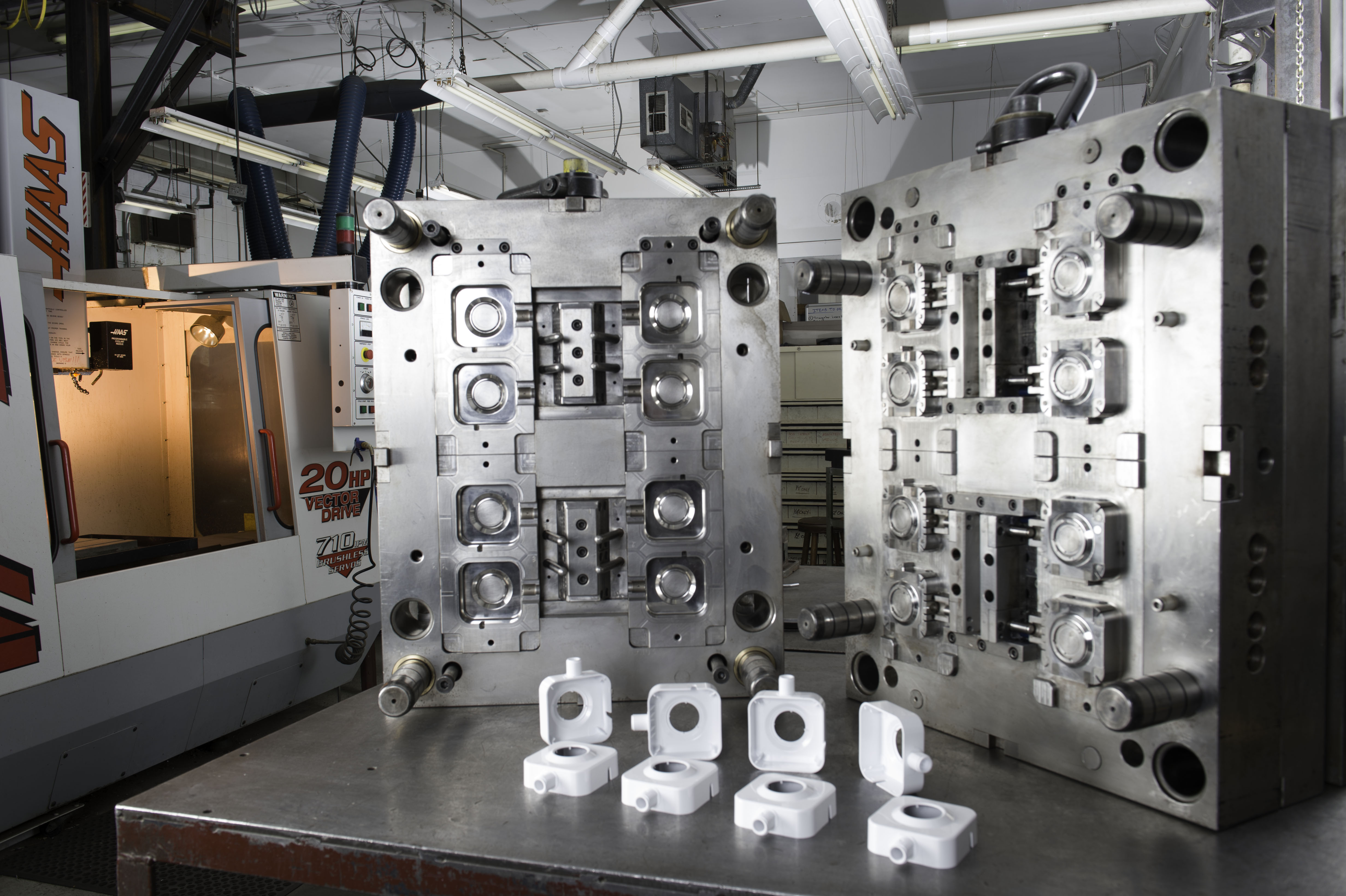

Tooling:

Engineering:

- Kubotek

- AutoCAD

- Surf cam 3 axis plus CAD/CAM

- File Import/Export-ACIS,

STEP, PARASOLID, DXF & IGES

Tool Room:

Milling

- 4 Bridgeports - Series one with read-outs

- Bridgeport 2 axis CNC

- RBI with XY readouts

- HAAS 3 axis CNC

Lathe

- Clausing & Metosa C14-40

Welding

- Lincoln Square Wave Tig 350

- Arc Welder

Grinding

- Chevalier Surface Grinder 16"x28" auto

- Chevalier Surface Grinder 6-18

- Kent Schultz surface grinder 6-12 New 07

- Scripta End Mill Sharpener

- Hardinge spinning fixture

- Baldor pedestal grinder

- Radius Dressers

Miscellaneous

- Dayton 25 Ton Press

- Sandblaster

- Lassy Tapper

- Sine Plates

- All associated tool room equipment

EDM

- Charmilles Form 20-60 amps, XYZ readouts, ISO 3R Tooling